1、 The rapid growth of epoxy propane industry scale

Epoxy propane, as a key extension direction of downstream fine chemicals in the propylene industry chain, has received unprecedented attention in the Chinese chemical industry. This is mainly due to its important position in fine chemicals and the development trend brought about by the industrial chain connection of new energy related products. According to statistical data, as of the end of 2023, the scale of China’s epoxy propane industry has exceeded 7.8 million tons per year, which has increased nearly tenfold compared to 2006. From 2006 to 2023, the industrial scale of epoxy propane in China showed an average annual growth rate of 13%, which is rare in the chemical industry. Especially in the past four years, the average growth rate of industry scale has exceeded 30%, showing an astonishing growth momentum.

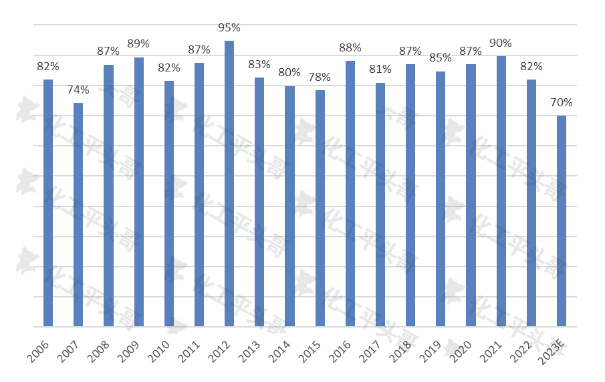

Figure 1 Annual operating rate changes of epoxy propane in China

Behind this rapid growth, there are multiple factors driving it. Firstly, as an important downstream extension of the propylene industry chain, epichlorohydrin is the key to achieving refined development in private enterprises. With the transformation and upgrading of the domestic chemical industry, more and more enterprises are paying attention to the field of fine chemicals, and epoxy propane, as an important part of it, has naturally received widespread attention. Secondly, the development experience of successful enterprises such as Wanhua Chemical has set a benchmark for the industry, and their successful industrial chain integration and innovative development models provide reference for other enterprises. In addition, with the rapid development of the new energy industry, the industrial chain connection between epoxy propane and new energy related products has also brought broad development space.

However, this rapid growth has also brought a series of problems. Firstly, the rapid expansion of industry scale has led to increasingly severe supply-demand contradictions. Although the market demand for epoxy propane continues to grow, the growth rate of supply is obviously faster, which leads to a continuous decline in the operating rate of enterprises and increasingly fierce market competition. Secondly, there is a serious phenomenon of homogeneous competition within the industry. Due to the lack of core technology and innovation capabilities, many enterprises lack differentiated competitive advantages in product quality, performance, and other aspects, and can only compete for market share through price wars and other means. This not only affects the profitability of enterprises, but also restricts the healthy development of the industry.

2、 The intensification of supply-demand contradictions

With the rapid expansion of the epoxy propane industry, the supply-demand contradiction is also becoming increasingly severe. In the past 18 years, the average operating rate of epoxy propane in China has been about 85%, maintaining a relatively stable trend. However, starting from 2022, the operating rate of epoxy propane will gradually decrease, and it is expected to drop to around 70% by 2023, which is a historical low. This change fully demonstrates the intensity of market competition and the intensification of supply-demand contradictions.

There are two main reasons for the intensification of supply-demand contradictions. On the one hand, with the rapid expansion of industry scale, more and more enterprises are entering the epoxy propane market, leading to intensified market competition. In order to compete for market share, companies have to lower prices and increase production, which leads to a continuous decline in operating rates. On the other hand, the downstream application areas of epoxy propane are relatively limited, mainly concentrated in the fields of polyether polyols, dimethyl carbonate, propylene glycol, and alcohol ethers. Among them, polyether polyols are the main downstream application field of epoxy propane, accounting for 80% or more of the total consumption of epoxy propane. However, the consumption growth rate in this field is consistent with the growth rate of China’s economy, and the industrial scale growth is less than 6%, which is significantly slower than the supply growth rate of epoxy propane. This means that although market demand is growing, the growth rate is far slower than the supply growth rate, leading to the intensification of supply-demand contradictions.

3、 The reduction of import dependence

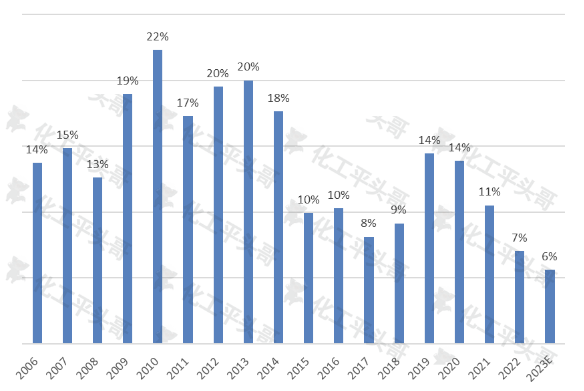

Import dependence is one of the main indicators for measuring the supply gap in the domestic market, and it is also an important parameter reflecting the level of import scale. In the past 18 years, the average import dependency of China’s epoxy propane has been around 14%, reaching a peak of 22%. However, with the rapid development of the domestic epoxy propane industry and the continuous increase in domestic scale, the import dependence has shown a decreasing trend year by year. It is expected that by 2023, China’s import dependence on epoxy propane will decrease to around 6%, reaching a historical low in the past 18 years.

Figure 2 Trend of China’s dependence on imported epoxy propane

The decrease in import dependence is mainly due to two factors. Firstly, with the rapid expansion of the domestic epoxy propane industry, the quality and performance of domestic products have been significantly improved. Many domestic enterprises have made significant breakthroughs in technological innovation and product research and development, resulting in the quality of domestically produced epoxy propane being almost the same as imported products. This has given domestic enterprises a greater competitive advantage in the market and reduced their dependence on imported products. Secondly, with the continuous increase in domestic epoxy propane production capacity, the market supply capacity has been significantly improved. This enables domestic enterprises to better meet market demand and reduce the demand for imported products.

However, the decrease in import dependence has also brought a series of problems. Firstly, with the continuous expansion of the domestic epoxy propane market and the continuous growth of demand, the supply pressure of domestic products is also increasing. If domestic enterprises are unable to further increase production and quality, the market supply-demand contradiction may further intensify. Secondly, with the decrease in import dependence, domestic enterprises are facing greater market competition pressure. In order to compete for market share and maintain competitiveness, domestic enterprises need to continuously improve their technological level and innovation capabilities.

4、 Analysis of future development situation

The Chinese epoxy propane market will face a series of profound changes in the future. According to statistical data, it is expected that the scale of China’s epoxy propane industry will exceed 14 million tons/year by 2030, and the average annual growth rate will remain at a high level of 8.8% from 2023 to 2030. This rapid growth rate will undoubtedly further exacerbate the supply pressure on the market and increase the risk of overcapacity.

The operating rate of an industry is often regarded as an important indicator for evaluating whether the market is surplus. When the operating rate is below 75%, there may be an excess in the market. The operating rate is directly influenced by the growth rate of the terminal consumer market. At present, the main downstream application field of epoxy propane is polyether polyols, which account for more than 80% of the total consumption. However, other application areas such as dimethyl carbonate, propylene glycol and alcohol ether, flame retardants, although present, have a relatively small proportion and limited support for the consumption of epichlorohydrin.

It is worth noting that the consumption growth rate of polyether polyols is basically consistent with the growth rate of China’s economy, and its industrial scale growth is less than 6%, significantly lower than the supply growth rate of epoxy propane. This means that while the growth rate on the consumer side is relatively slow, the rapid growth on the supply side will further deteriorate the supply and demand environment of the epoxy propane market. In fact, 2023 may already be the first year of oversupply in China’s epoxy propane industry, and the probability of oversupply in the long term remains high.

Epoxy propane, as a transitional product in the rapid development of China’s chemical industry, has its unique characteristics. It requires products to have the characteristics of homogeneity and scale, while having relatively low investment and technological barriers, and easy access to raw materials. In addition, it also needs to have mid-range attributes in the industrial chain, which means it can achieve downstream extension of the industrial chain. These types of products play a crucial role in the refined development of the chemical industry, but also face the risk of market homogenization shocks.

Therefore, for enterprises producing epoxy propane, how to seek differentiation in the development of the industrial chain in fierce market competition and how to use more advanced technology to reduce production costs will become important strategic considerations for their future development.

Post time: Feb-28-2024