In the first half of the year, the epoxy resin market showed a weak downward trend, with weak cost support and weak supply and demand fundamentals jointly exerting pressure on the market. In the second half of the year, under the expectation of the traditional consumption peak season of “nine gold and ten silver”, the demand side may experience phased growth. However, considering that the supply of epoxy resin market may continue to grow in the second half of the year, and the demand side’s growth is limited, it is expected that the low range of epoxy resin market in the second half of the year will fluctuate or rise in stages, but the space for price increase is limited.

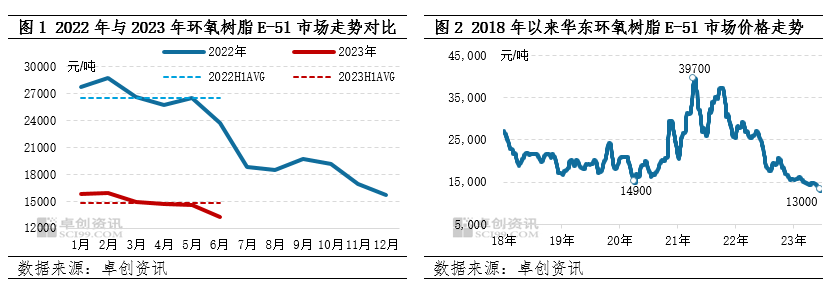

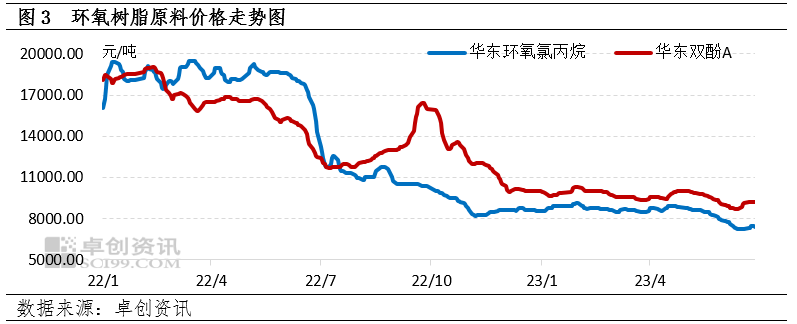

Due to the slow recovery of domestic economic vitality in the first half of the year, downstream and terminal demand for epoxy resin was lower than expected. Due to the release of new domestic equipment production capacity and weak support for raw material costs, epoxy resin prices entered a downward trend in February, exceeding expectations for a decline. From January to June 2023, the average price of East China epoxy resin E-51 (acceptance price, delivery price, including tax, barrel packaging, automobile transportation, the same below) was 14840.24 yuan/ton, a decrease of 43.99% compared to the same period last year (see Figure 1). On June 30th, the domestic epoxy resin E-51 closed at 13250 yuan/ton, a decrease of 13.5% compared to the beginning of the year (see Figure 2).

Insufficient cost support for epoxy resin dual raw materials

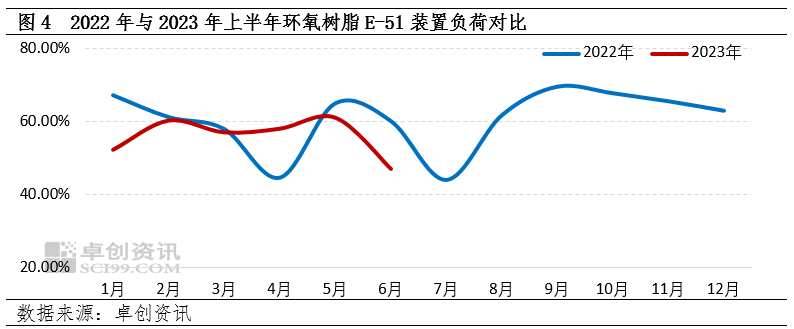

In the first half of the year, the focus of domestic negotiations on bisphenol A fluctuated and decreased. Compared with the same period last year, the average market price of bisphenol A in East China was 9633.33 yuan/ton, down 7085.11 yuan/ton, down 42.38%. During this period, the highest negotiation is 10300 yuan/ton at the end of January, and the lowest negotiation is 8700 yuan/ton in mid June, with a price range of 18.39%. The downward pressure on the price of bisphenol A in the first half of the year mainly came from the supply and demand aspects and cost aspects, with changes in the supply and demand pattern having a more significant impact on prices. In the first half of 2023, the domestic production capacity of bisphenol A increased by 440000 tons, and the domestic production increased significantly year-on-year. Although the consumption of bisphenol A has increased year-on-year, the development of the terminal industry shows strong expectations of weakness, but the growth rate is not as fast as the supply side, and the market supply and demand pressure has increased. At the same time, the raw material phenol acetone has also decreased synchronously, coupled with rising macroeconomic risk sentiment, market confidence is generally weak, and many factors have a negative impact on the price of bisphenol A. In the first half of the year, the bisphenol a market also experienced a staged rebound. The main reason is a significant decrease in product profits and a significant loss in equipment gross profit. Part of the bisphenol A equipment has been reduced in operation, and downstream factories have concentrated on restocking to support price increases.

The domestic Epichlorohydrin market was weak and volatile in the first half of the year, and entered the downward channel in late April. The price of Epichlorohydrin fluctuated from the beginning of the year to the first ten days of April. The price increase in January was mainly due to the improvement of orders for downstream epoxy resin before the festival, which increased the purchase enthusiasm of raw material Epichlorohydrin. The factory has delivered more contracts and early orders, resulting in a shortage of stock in the market, leading to price increases. The decline in February was mainly due to sluggish terminal and downstream demand, hindered factory shipments, high inventory pressure, and a narrow decline in prices. In March, downstream epoxy resin orders were sluggish, resin positions were high, and demand was difficult to significantly improve. Market prices fluctuated relatively low, and some chlorine plants were reduced in cost and inventory pressure to stop. In mid April, due to the parking of some factories on site, spot supply in some areas was tight, resulting in an increase in new market orders and negotiations on actual orders. From the end of April to mid June, the differentiation of multi process gross profit gradually became apparent, coupled with weak buying sentiment from upstream and downstream, resulting in a decline in the market after actual order negotiations. As the end of June approaches, the cost pressure of propylene method is relatively high, and the sentiment of holders in the market is gradually increasing. Some downstream companies only need to follow up, and the market trading atmosphere has briefly warmed up, resulting in a narrow increase in actual order prices. In the first half of 2023, the average price of Epichlorohydrin in East China market will be about 8485.77 yuan/ton, down 9881.03 yuan/ton or 53.80% compared with the same period last year.

The mismatch between supply and demand in the domestic epoxy resin market is intensifying

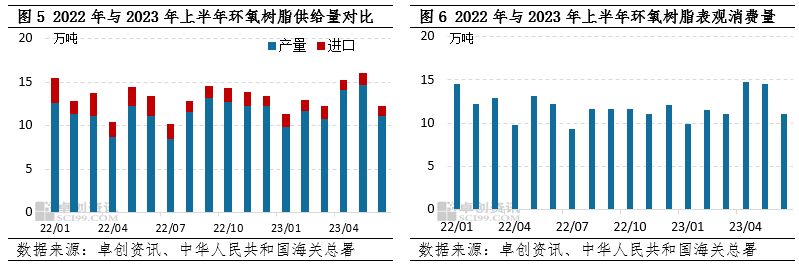

Supply side: In the first half of the year, new production capacity of around 210000 tons, including Dongfang Feiyuan and Dongying Hebang, was released, while the downstream demand side growth rate was lower than the supply side, exacerbating the mismatch between supply and demand in the market. The average operating load of the epoxy resin E-51 industry in the first half of the year was around 56%, a decrease of 3 percentage points compared to the same period last year. At the end of June, the overall market operation decreased to around 47%; From January to June, the production of epoxy resin was approximately 727100 tons, a year-on-year increase of 7.43%. In addition, the import of epoxy resin from January to June was approximately 78600 tons, a decrease of 40.14% compared to the same period last year. The main reason is that the domestic supply of epoxy resin is sufficient and the import volume is relatively small. The total supply reached 25.2 million tons, an increase of 7.7% compared to the same period last year.; The expected new production capacity in the second half of the year is 335000 tons. Although some equipment may delay production due to profit levels, supply and demand pressures, and price declines, it is an undeniable fact that epoxy resin production capacity will further accelerate the pace of energy expansion compared to the first half of the year, and market supply capacity may continue to increase. From the perspective of demand, the recovery of terminal consumption level is slow. It is expected that new stimulus consumption policies will be introduced in the second half of the year. With the introduction of a series of policy measures to promote sustained economic improvement, the spontaneous repair of vivid energy within the economy will be superimposed, and China’s economy is expected to continue to improve marginally, which is expected to drive the demand for epoxy products.

Demand side: After the optimization of epidemic prevention policies, the domestic economy officially entered the repair channel in November 2022. However, after the epidemic, the economic recovery is still dominated by a “scenario based” recovery, with tourism, catering and other industries taking the lead in recovery and showing strong momentum. The demand driven effect on industrial products is lower than expected. The same applies to epoxy resin, with lower end demand than expected. The downstream coatings, electronics, and wind power industries have recovered slowly, with overall weak demand side. The apparent consumption of epoxy resin in the first half of the year was approximately 726200 tons, a decrease of 2.77% compared to the same period last year. As supply and demand increase and decrease, the mismatch between supply and demand of epoxy resin further intensifies, leading to a decrease in epoxy resin.

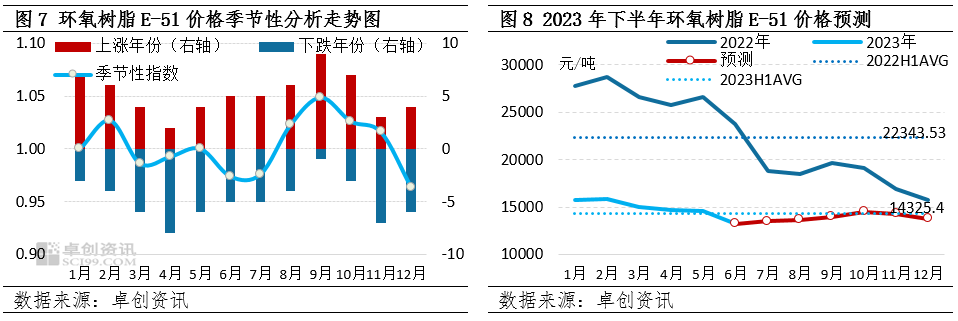

Epoxy resin has obvious seasonal characteristics, with a high probability of increase from September to October

The fluctuation of epoxy resin prices has certain seasonal characteristics, specifically manifested as a narrow rise in the market after the first nine months of fluctuations, with downstream stocking demand concentrated in January and February before the Spring Festival to support resin prices; September October has entered the traditional consumption peak season of “Golden Nine Silver Ten”, with a high probability of price increase; March May and November December gradually enter the consumption off-season, with a large inventory of raw materials for downstream digestion of epoxy resin, and a high probability of market price decline. It is expected that the epoxy resin market will continue the above seasonal fluctuation pattern in the second half of this year, combined with the changes in energy market prices and the domestic economic recovery process.

It is expected that the high point in the second half of the year will likely occur in September and October, while the low point may occur in December. The epoxy resin market fluctuates in the low range for half a year, and the mainstream price range may be between 13500-14500 yuan/ton.

Post time: Jul-18-2023