As of July 2023, the total scale of epoxy resin in China has exceeded 3 million tons per year, showing a rapid growth rate of 12.7% in recent years, with the industry’s growth rate exceeding the average growth rate of bulk chemicals. It can be seen that in recent years, the increase in epoxy resin projects has been rapid, and many enterprises have invested in and planned to build a huge project. According to statistics, the construction scale of epoxy resin in China will exceed 2.8 million tons in the future, and the industry scale growth rate will continue to increase to around 18%.

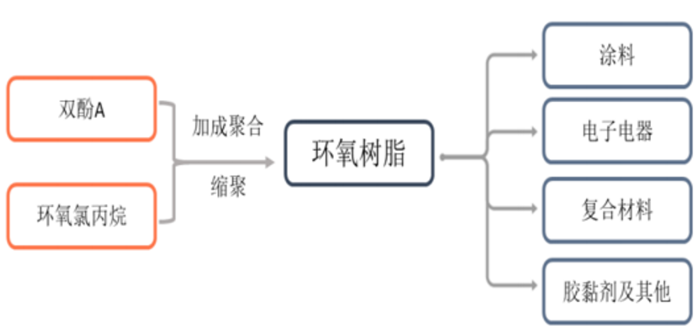

Epoxy resin is the polymerization production of bisphenol A and Epichlorohydrin. It has the characteristics of high mechanical properties, strong cohesion, dense molecular structure, excellent bonding performance, small curing shrinkage (product size is stable, internal stress is small, and it is not easy to crack), good insulation, good corrosion resistance, good stability, and good heat resistance (up to 200 ℃ or higher). Therefore, it is widely used in coatings, electronic appliances, composite materials, adhesives and other fields.

The production process of epoxy resin is generally divided into one-step and two-step methods. One step method is to produce epoxy resin by direct reaction of bisphenol A and Epichlorohydrin, which is commonly used to synthesize low molecular weight and medium molecular weight epoxy resin; The two-step method involves the continued reaction of low molecular resin with bisphenol A. High molecular weight epoxy resin can be synthesized through one-step or two-step methods.

One step process is to shrink bisphenol A and Epichlorohydrin under the action of NaOH, that is, to carry out ring opening and closed loop reactions under the same reaction conditions. At present, the largest production of E-44 epoxy resin in China is synthesized through a one-step process. The two-step process is that bisphenol A and Epichlorohydrin generate diphenyl propane chlorohydrin ether intermediate through Addition reaction in the first step under the action of catalyst (such as Quaternary ammonium cation), and then conduct closed-loop reaction in the presence of NaOH to generate epoxy resin. The advantage of two-step method is short reaction time; Stable operation, small temperature fluctuations, easy to control; Short alkali addition time can avoid excessive hydrolysis of epichlorohydrin. The two-step process for synthesizing epoxy resin is also widely used.

Image source: China Industrial Information

According to relevant statistics, many enterprises will enter the epoxy resin industry in the future. For example, 50000 tons of Hengtai electronic materials/year equipment will be put into production in late 2023, and 150000 tons of Mount Huangshan Meijia new materials/year equipment will be put into production in October 2023. Zhejiang Zhihe New Materials’ 100000 ton/year equipment is planned to be put into production by the end of 2023, South Asia Electronic Materials (Kunshan) Co., Ltd. plans to put into production 300000 ton/year equipment and equipment around 2025, and Yulin Jiuyang High tech Materials Co., Ltd. plans to put into production 500000 ton/year equipment around 2027. According to incomplete statistics, it will double in the future around 2025.

Why are everyone investing in epoxy resin projects? The reasons for the analysis are as follows:

Epoxy resin is an excellent electronic packaging material

Electronic sealant refers to a series of electronic adhesives and adhesives used to seal electronic devices, including sealing, sealing, and potting. Packaged electronic devices can play a waterproof, shockproof, dustproof, anti-corrosion, heat dissipation, and confidentiality role. Therefore, the glue to be packaged has the characteristics of high temperature resistance, low temperature resistance, high Dielectric strength, good insulation, environmental protection and safety.

Epoxy resin has excellent heat resistance, electrical insulation, sealing, dielectric properties, mechanical properties, and small shrinkage and chemical resistance. After being mixed with curing agents, it can have better operability and all the material characteristics required for electronic material packaging, and is widely used in fields such as electronic material packaging.

According to data from the National Bureau of Statistics, the growth rate of the electronic information manufacturing industry in 2022 increased by 7.6% year-on-year, and the consumption growth rate in some electronic material fields exceeded 30%. It can be seen that China’s electronic industry is still in a trend of rapid growth, especially in forward-looking electronic industries such as semiconductors and 5G In fields such as artificial intelligence and the Internet of Things, the growth rate of market size has always been far ahead.

At present, some epoxy resin companies in China are changing their product structure and increasing the product share of epoxy resin brands related to the electronic materials industry. In addition, most of the epoxy resin enterprises planned to be built in China mainly focus on electronic material product models.

Epoxy resin is the main material for wind turbine blades

Epoxy resin has excellent mechanical properties, chemical stability, and corrosion resistance, and can be used as blade structural components, connectors, and wind power generation coatings. Epoxy resin can provide high strength, high stiffness, and fatigue resistance, ensuring the stability and reliability of blades, including the supporting structure, skeleton, and connecting parts of the blades. In addition, epoxy resin can also improve the wind shear resistance and impact resistance of blades, reduce the vibration and noise of blades, and improve the efficiency of wind power generation.

In the coating of wind turbine blades, the application of epoxy resin is also very important. By coating the surface of the blades with epoxy resin, the wear resistance and UV resistance of the blades can be improved, and the service life of the blades can be extended. At the same time, it can also reduce the weight and resistance of blades and improve the efficiency of wind power generation.

Therefore, epoxy resin needs to be widely used in many aspects of the wind power industry. At present, composite materials such as epoxy resin, carbon fiber, and polyamide are mainly used as blade materials for wind power generation.

China’s wind power is in the leading position in the world, with an average annual growth of more than 48%. The manufacturing of wind power related equipment is the main driving force for the rapid growth of epoxy resin product consumption. It is expected that the speed of China’s wind power industry will maintain a growth of more than 30% in the future, and the consumption of epoxy resin in China will also show an explosive growth trend.

Customized and special epoxy resins will be the mainstream in the future

The downstream application fields of epoxy resin are very extensive. Although driven by the development of the new energy industry, the industry has developed rapidly in scale, the development of customization, differentiation, and specialization will also become one of the main development directions of the industry.

The development direction of epoxy resin customization has the following application directions. Firstly, halogen-free copper circuit board has potential demand for consumption of linear phenolic epoxy resin and Bisphenol F epoxy resin; Secondly, the consumption demand for o-methylphenol formaldehyde epoxy resin and hydrogenated bisphenol A epoxy resin is rapidly growing; Thirdly, food grade epoxy resin is a product further purified by traditional epoxy resin, which has certain development prospects when applied to metal cans, beer, carbonated beverages, and fruit juice cans; Fourth, the multi-functional resin production line is a production line that can produce all epoxy resins and raw materials, such as clean low-grade composite resins. β- Phenol type epoxy resin, liquid crystal epoxy resin, special structure low viscosity DCPD type epoxy resin, etc. These epoxy resins will have broad development space in the future.

On the one hand, it is driven by consumption in the downstream electronics field, and on the other hand, a wide range of application fields and the emergence of numerous high-end models have brought many potential consumption spaces to the epoxy resin industry. It is expected that the consumption of China’s epoxy resin industry will maintain a rapid growth of over 10% in the future, and the development of the epoxy resin industry can be expected.

Post time: Aug-04-2023