MMA, fully known as methyl methacrylate, is an important raw material for the production of polymethyl methacrylate (PMMA), which is also commonly known as acrylic. With the development of PMMA’s industry adjustment, the development of MMA industry chain has been pushed backwards. According to the survey, there are three mainstream production processes of MMA, which are acetone cyanohydrin method (ACH method), ethylene carbonylation method and isobutylene oxidation method (C4 method). Currently, the ACH method and C4 method are mainly used in Chinese production enterprises, and there is no industrial production unit for ethylene carbonylation method.

Our study of the MMA value chain analyzes the above three production processes and the main downstream PMMA price halo respectively.

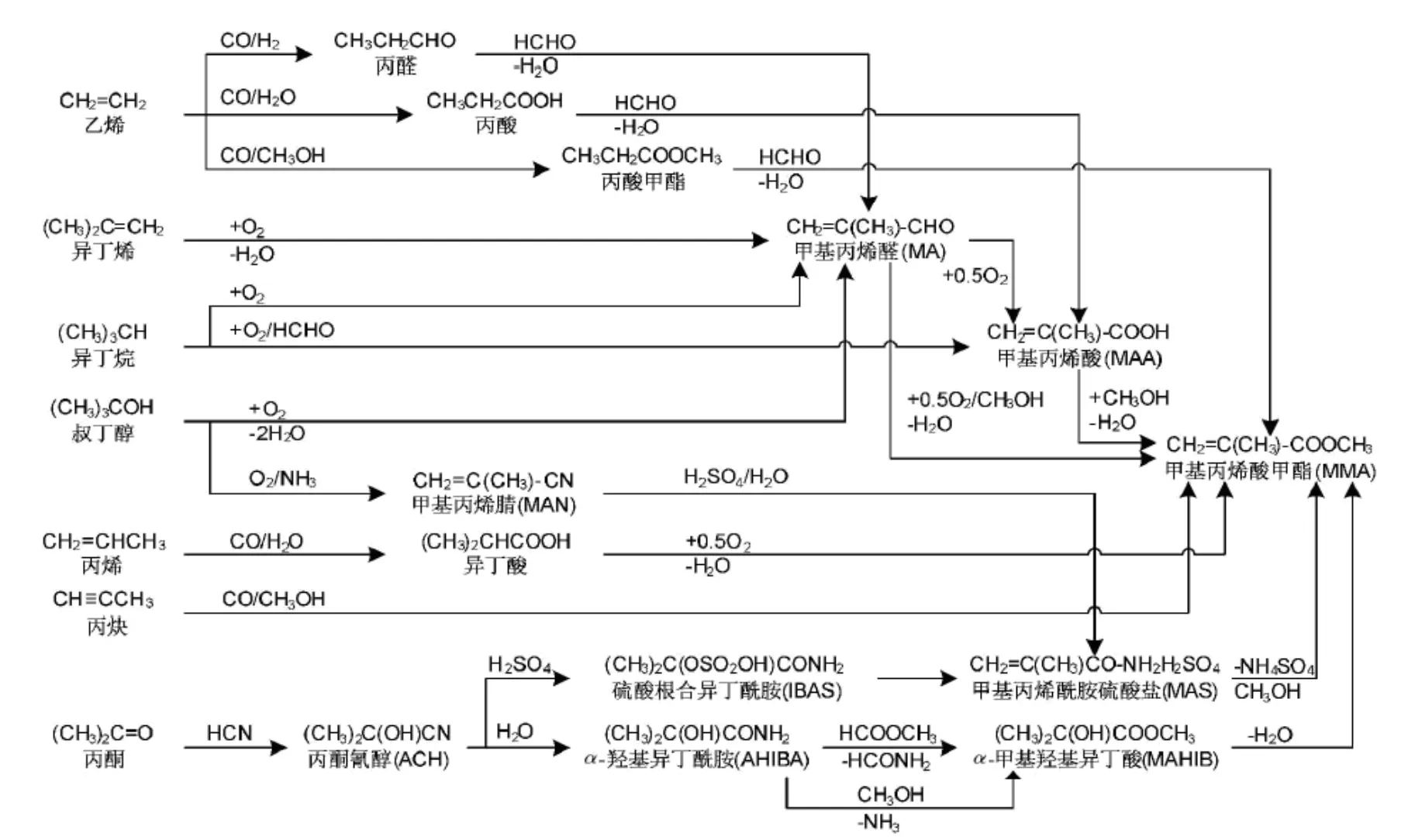

Figure 1 Flow chart of MMA industry chain with different processes (Photo source: Chemical Industry)

Industry chain I: ACH method MMA value chain

In the production process of ACH method MMA, the main raw materials are acetone and hydrocyanic acid, where hydrocyanic acid is produced by-product of acrylonitrile, and auxiliary methanol, so the industry generally uses acetone, acrylonitrile and methanol as the cost to calculate the composition of raw materials. Among them, 0.69 tons of acetone and 0,32 tons of acrylonitrile and 0.35 tons of methanol are calculated as unit consumption. In the cost composition of ACH method MMA, acetone cost accounts for the largest proportion, followed by hydrocyanic acid produced by-product of acrylonitrile, and methanol accounts for the smallest proportion.

According to the price correlation test of acetone, methanol and acrylonitrile in the past three years, it is found that the correlation of ACH method MMA with acetone is around 19%, with methanol is around 57% and according to acrylonitrile is around 18%. It can be seen that there is a gap between this and the cost share in MMA, where the high share of acetone for the cost of MMA can not be reflected in its price fluctuations on the price fluctuations of ACH method MMA, while the price fluctuations of methanol have a greater impact on the price of MMA than acetone.

However, the cost share of methanol is only at about 7%, and the cost share of acetone is about 26%. For the study of the value chain of MMA, it is more important to look at the cost changes of acetone.

Overall, the value chain of ACH MMA mainly comes from the cost fluctuations of acetone and methanol, among which acetone has the greatest impact on the value of MMA.

Industry chain II: C4 method MMA value chain

For the value chain of C4 method MMA, its raw materials are isobutylene and methanol, among which isobutylene is a high-purity isobutylene product, which comes from MTBE cracking production. And methanol is an industrial methanol product, which comes from coal production.

According to the cost composition of C4 MMA, the variable cost isobutene unit consumption is 0.82 and methanol is 0.35. With the progress of everyone in the production technology, the unit consumption has been reduced to 0.8 in the industry, which has reduced the cost of C4 MMA to some extent. The rest are fixed costs, such as water, electricity and gas costs, financial costs, sewage treatment costs and others.

In this, the share of high-purity isobutylene in the cost of MMA is about 58%, and the share of methanol in the cost of MMA is about 6%. It can be seen that isobutene is the largest variable cost in C4 MMA, where the price fluctuation of isobutene has a huge impact on the cost of C4 MMA.

The value chain impact for high purity isobutene is traced back to the price fluctuation of MTBE, which consumes 1.57 unit consumption and constitutes more than 80% of the cost for high purity isobutene. The cost of MTBE in turn comes from methanol and pre-ether C4, where the composition of pre-ether C4 can be linked to the feedstock for the value chain.

In addition, it should be noted that high purity isobutene can be produced by tert-butanol dehydration, and some enterprises will use tert-butanol as the basis for MMA cost calculation, and its unit consumption of tert-butanol is 1.52. According to the calculation of tert-butanol 6200 yuan/ton, tert-butanol accounts for about 70% of MMA cost, which is larger than isobutene.

In other words, if the price linkage of tert-butanol is used, the fluctuation of the value chain of C4 method MMA, the influence weight of tert-butanol is greater than that of isobutene.

To sum up, in C4 MMA, the influence weight for value fluctuation is ranked from high to low: tert-butanol, isobutene, MTBE, methanol, crude oil.

Industry chain III: Ethylene carbonylation MMA value chain

There is no industrial production case of MMA by ethylene carbonylation in China, so the impact of value fluctuation cannot be speculated by actual industrial production. However, according to the unit consumption of ethylene in ethylene carbonylation, ethylene is the main cost impact on the MMA cost composition of this process, which is more than 85%.

Industry chain IV: PMMA value chain

PMMA, as the main downstream product of MMA, accounts for more than 70% of the annual consumption of MMA.

According to the value chain composition of PMMA, in which the consumption unit consumption of MMA is 0.93, MMA is calculated according to 13,400 yuan/ton and PMMA is calculated according to 15,800 yuan/ton, the variable cost of MMA in PMMA accounts for about 79%, which is a relatively high percentage.

In other words, the price fluctuation of MMA has a strong influence on the value fluctuation of PMMA, which is a strong correlation influence. According to the correlation of price fluctuation between the two in the past three years, the correlation between the two is more than 82%, which belongs to the influence of strong correlation. Therefore, the price fluctuation of MMA will cause the price fluctuation of PMMA in the same direction with a high probability.

Post time: May-31-2022