The chemical market prices have continued to decline for about half a year. Such a prolonged decline, while oil prices remain high, has led to an imbalance in the value of most links in the chemical industry chain. The more terminals in the industrial chain, the greater the pressure on the cost of the industrial chain. Therefore, many chemical products are currently in a state of high cost but sluggish consumer market, resulting in poor production economy of many chemical products.

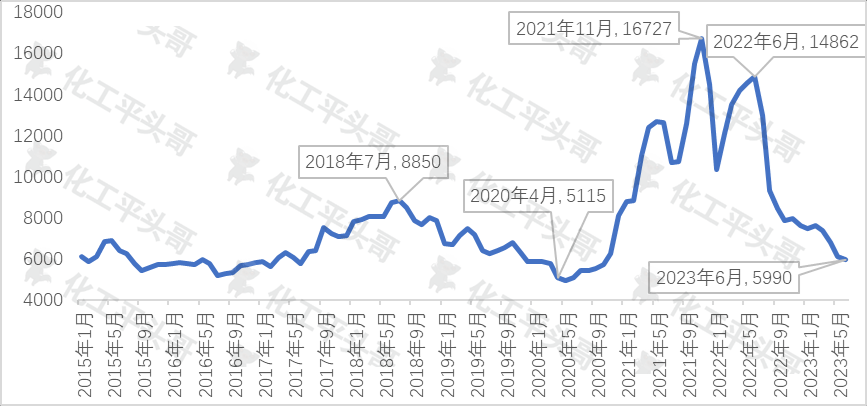

The market price of vinyl acetate has also continued to decline. In recent years, the market price of vinyl acetate has dropped from 14862 yuan/ton in June 2022 to June 2023, continuously declining for nearly a year, with the lowest price dropping to 5990 yuan/ton. From the price trends of the past few years, the lowest price in history appeared in April 2020, the lowest price appeared at 5115 yuan/ton, the highest price appeared in November 2021, and the highest price appeared at 16727 yuan/ton.

Although the price of vinyl acetate has been declining for a consecutive year, the production profit of vinyl acetate remains high and the production economy is good. Why can vinyl acetate maintain a high level of prosperity?

Different production processes for vinyl acetate result in varying profits and losses

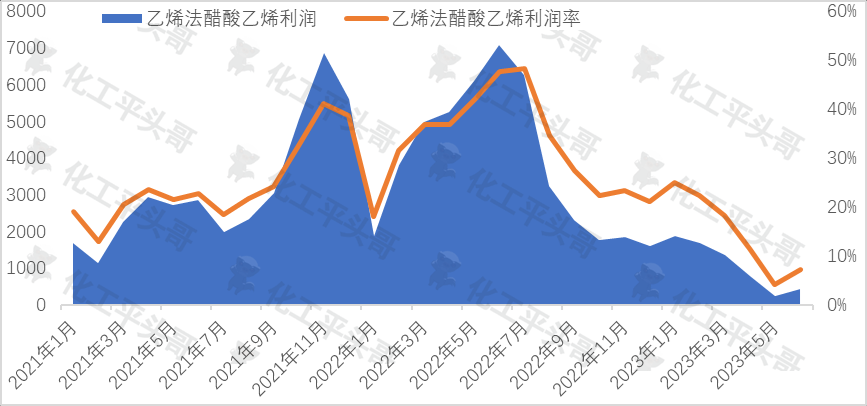

According to the change of the profit rate of vinyl acetate produced by ethylene method, the profit rate of vinyl acetate produced by ethylene method has always been in a profitable state in the past few years, the highest profit rate has reached 50% or more, and the average profit rate is about 15%. It can be seen that ethylene based vinyl acetate has been a relatively profitable product in the past two years, with a good overall prosperity and stable profit margins.

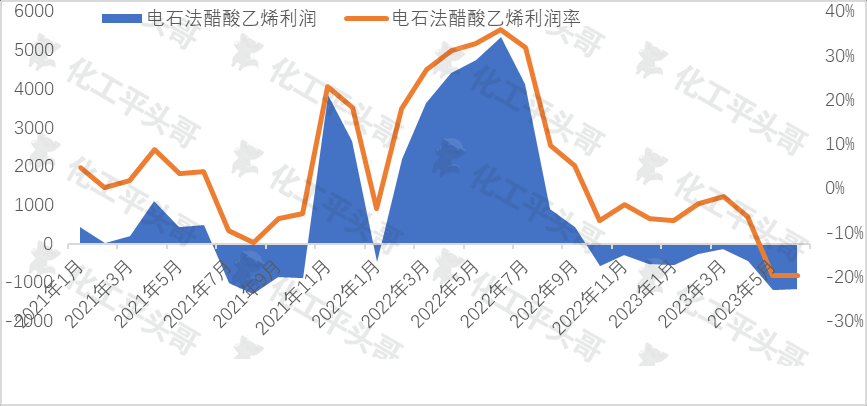

From the perspective of calcium carbide method vinyl acetate, in the past two years, except for significant profits from March 2022 to July 2022, all other periods have been in a state of loss. As of June 2023, the profit margin level of calcium carbide method vinyl acetate was around 20% loss, and the average profit margin of calcium carbide method vinyl acetate in the past two years was 0.2% loss. It can be seen that the prosperity of the calcium carbide method for vinyl acetate is poor, and the overall situation is showing a loss.

It can be seen that it is not a common phenomenon for vinyl acetate to be at a high profit level. Only the ethylene method of vinyl acetate production is currently in a profitable state, while the carbide method has always been in a loss state in the past few years.

Analysis of maintaining high profitability of ethylene based vinyl acetate production

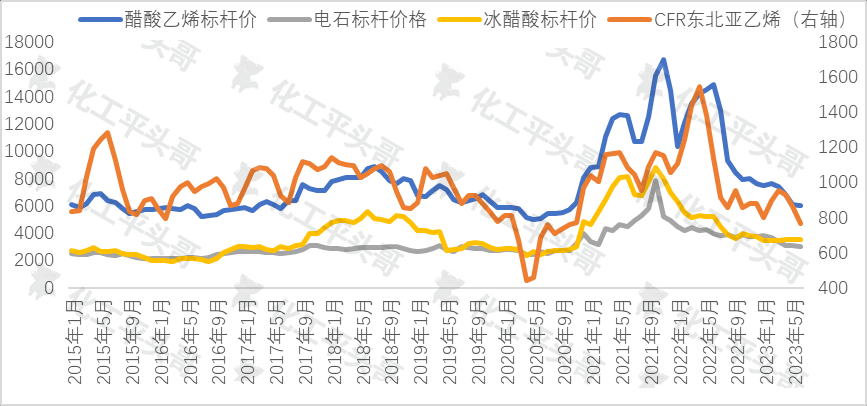

1. The proportion of raw material costs varies in different production processes. In ethylene based vinyl acetate production, the unit consumption of ethylene is 0.35 and the unit consumption of glacial acetic acid is 0.72. According to the average price level in June 2023, the proportion of ethylene in ethylene based vinyl acetate production is about 37%, while glacial acetic acid is 45%. Therefore, the price fluctuation of glacial acetic acid has the greatest impact on the cost change of ethylene based vinyl acetate production, followed by ethylene.

As for the cost of calcium carbide method for vinyl acetate, calcium carbide accounts for about 47% of the cost of calcium carbide method for vinyl acetate, and glacial acetic acid accounts for about 35% of the cost of calcium carbide method for vinyl acetate. Therefore, in the calcium carbide method of vinyl acetate, the change in the price of calcium carbide has a greater impact on the cost, which is greatly different from the cost impact of the ethylene method.

2. The significant decrease in raw materials ethylene and glacial acetic acid has led to a significant decrease in costs. According to relevant data, in the past year, the price of CFR Northeast Asia ethylene has decreased by 33%, and the price of glacial acetic acid has decreased by 32%. However, the production cost of vinyl acetate using calcium carbide method is mainly limited by the price of calcium carbide. In the past year, the price of calcium carbide has decreased by 25%.

Therefore, from the perspective of two different production processes, the raw material cost of ethylene method vinyl acetate has significantly decreased, and the cost reduction is greater than that of calcium carbide method.

3. Although the price of vinyl acetate has decreased, the decline is not as significant as other chemicals. In the past year, the price of vinyl acetate has decreased by 59%, which appears to be a significant decrease, but the price of other chemicals has decreased even more.

Vinyl acetate has always maintained a certain profit margin, mainly due to the cost reduction caused by the decrease in raw material prices, rather than the support of the consumer market for its prices. This is also the current situation of value transmission in the vinyl acetate industry chain. From the current situation of the Chinese chemical market in the short term, it is difficult to fundamentally change the weak state of the Chinese chemical market without large-scale consumer market stimulus policies. It is expected that the value chain of vinyl acetate will continue to maintain a downward transmission logic, and it is expected that the production profits in the future end consumer market, especially for polyethylene and EV products, will be maintained by reducing the profits of vinyl acetate.

Post time: Jun-25-2023