factory customized Modified Plastics Manufacturer - Phenol Formaldehyde Resin CAS 9003-35-4 High Quality And Low Price – Chemwin Detail:

Product Name:phenolic resin

Molecular format:

CAS No:9003-35-4

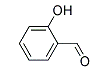

Product molecular structure:

Chemical Properties:

Phenol-formaldehyde resin is prepared as follows:

C6H5OH+H2C=O —> [-C6H2(OH)CH2-]n

One-Stage Resins. The ratio of formaldehyde to phenol is high enough to allow the thermosetting process to take place without the addition of other sources of cross-links.

Two-Stage Resins. The ratio of formaldehyde to phenol is low enough to prevent the thermosetting reaction from occurring during manufacture of the resin. At this point the resin is termed novolac resin. Subsequently, hexamethylenetetramine is incorporated into the material to act as a source of chemical cross-links during the molding operation (and conversion to the thermoset or cured state).

Application:

Phenolic resins are used for low-cost partsrequiring good electrical insulating properties,heat resistance, or chemical resistance. Theaverage shelf life of this resin is about 1 monthat 21.1°C. This can be extended by storing it ina refrigerator at 1.6 to 10°C. Varying the catalyst(according to the thickness of the cast) andraising the cure temperature to 93°C will alterthe cure time from as long as 8 h to as short as15 min.

Some shrinkage occurs in the finished casting(0.012 to 0.6 mm/mm), depending on thequantity of filler, amount of catalyst, and therate of cure. Faster cure cycles produce a higherrate of shrinkage. Since the cure cycle can beaccelerated, phenolics are used in short-runcasting operations.

Cast phenolic parts are easily removed fromthe mold if the parting agents recommended bythe supplier are used. Posteuring improves thebasic properties of the finished casting.

Product detail pictures:

Related Product Guide:

We're committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for factory customized Modified Plastics Manufacturer - Phenol Formaldehyde Resin CAS 9003-35-4 High Quality And Low Price – Chemwin , The product will supply to all over the world, such as: Lyon, Iraq, Surabaya, All the employees in factory, store, and office are struggling for one common goal to provide better quality and service. Real business is to get win-win situation. We would like to provide more support for customers. Welcome all nice buyers to communicate details of our products with us!

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Top